1.About the machine

Regal Spray Immunization Machine is a semi-automatic box type spray immunization machine, which is suitable for spray immunization of poultry vaccine for day-old chickens. It is commonly used for immunization of IB, ND, TRT and Coccidiosis vaccines. For the immunization of special vaccines, please consult your veterinary technician.

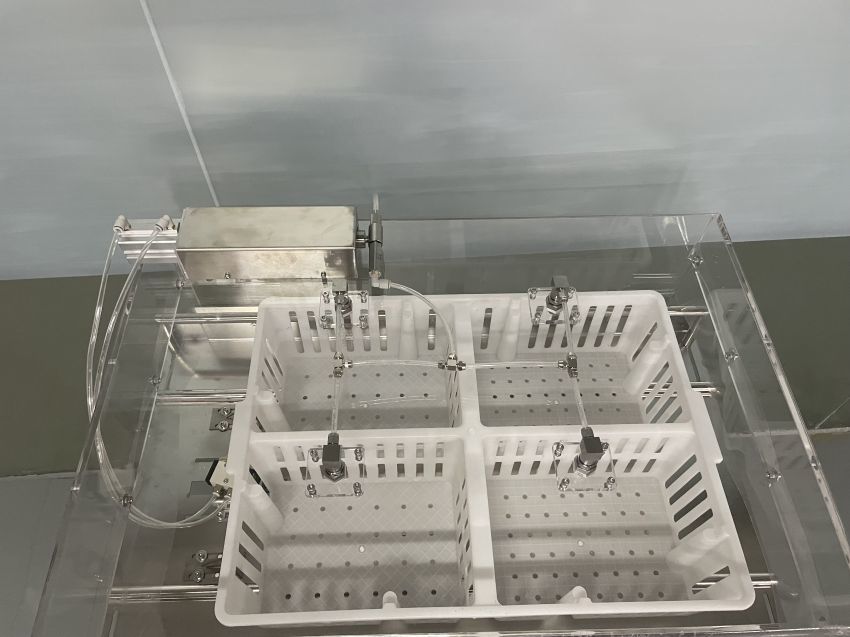

When in use, the operator will place the chicken box on the slide rail and place in proper position by pushing and pulling. When the front of the chicken box touches the trigger, the four nozzles will automatically spray the vaccine.

Regal Spray Immunization Machine is made of stainless steel. Its power comes from compressed air. The start and end of spray are controlled by a pneumatic piston, which is made of special materials with high strength and wear resistance.

All connecting tubes are fast connected. You only need to unscrew the nut outside the connector to split the connecting tube. Before that, please turn off the air compressor. To connect the new tube, just insert it into the quick connector.

If the vaccine you use cannot be dissolved in water for a long time, you can shake the vaccine barrel at regular intervals. The capacity of the vaccine barrel is 5 liters, which can be put into the autoclave for sterilization after being emptied.

2.Compressed air

Regal Spray Immunization Machine works with compressed air, which should reach 0.4-0.9mpa (57-128psi). One ordinary compressor with a minimum of 1.5 horsepower is enough. Clean and dry air is helpful for the maintenance of the air compressor, and the residual solution in the vaccine barrel should be removed once a week. The air supplied by the compressor cannot contact the vaccine. Before it enters the machine, the filter (30 μ) installed by Regal Spray Immunization Machine filters it, which it is very important for the machine to maintain good performance.

3. Safety and health

Poultry vaccine is a biological product, which has the risk of irritating the eyes and lungs of users. For safety and health reasons, please accept the following suggestions:

l Read the instructions and data sheets attached to the vaccine and follow the recommendations.

l The user should wear a filter mask/respirator with goggles, and wear protective clothing.

l Before disassembling any parts of Regal Spray Immunization Machine, be sure to turn off the air supply.

l Only inoculate healthy chickens and dilute the vaccine with distilled water.

l Ensure that trained personnel operate Regal Spray Immunization Machine and maintain the machine according to the cleaning/maintenance instructions in this manual.

l If you have any questions, please consult your veterinarian.

4. Vaccine dilution

Use only clean distilled water or deionized water to dilute the vaccine. Make sure that the water does not contain any chlorides, disinfectants or metals. Do not use disinfectants on machine that directly contact the vaccine (such as vaccine tube, vaccine barrel, measuring cylinder), and do not touch disinfectants before preparing the vaccine solution.

Calculate the total water consumption according to the following formula:

Spray amount per chicken box (ml) × Number of chicken boxes=total water consumption

To ensure a safe space, you can add 50-100ml more water based on the total water consumption.

We recommend that the minimum amount of spray for each chicken box be at least 10ml, and ask your veterinarian to determine whether the dose is suitable for your conditions. When spray with heavy fog, the chicken will look a little wet, so the chicken should stay in the chicken box for a period of time before loading. It is feasible to reduce the amount of spray within certain limits, but you must know that if the area of the chicken box covered by the droplets decreases due to the reduction of the amount of spray, the immune effect will be affected.

5. Droplet diameter

The droplet diameter shown in the table is the estimated average (in microns). You should know that some fog drops will be larger or smaller than the estimated value. The condition in the table is at 20 ℃, and the amount of spray is 15ml.

| Air pressure Mpa(psi) |

Vaccine pressure Mpa(psi) |

Droplet diameter μm |

| 0.4(57) | 0.13(18) | 190 |

| 0.5(71) | 0.18(26) | 175 |

| 0.6(86) | 0.26(37) | 162 |

It is not recommended to use in spray immunized Mycoplasma positive chickens (it will cause serious immune reaction). If you still decide to do this, you must select the maximum fog drop.

6.Immunization test

We recommend that the immunization test be carried out the day before the actual use of Regal Spray Immunization Machine.

First of all, clean water must be used for the test. The test can help you get familiar with the use of the machine, the coverage of spray and the humidity of chickens after spray.

Secondly, we suggest that a small amount of chicken be used for immunization test to observe the inoculation reaction. Once the vaccination reaction is normal, a large number of chickens can be immunized.

7.Pressure adjustment

Pull out the black knob upwards, turn it clockwise to increase the pressure, and turn it counterclockwise to decrease the pressure. The droplet diameter will decrease with the increase of pressure and increase with the decrease of pressure.

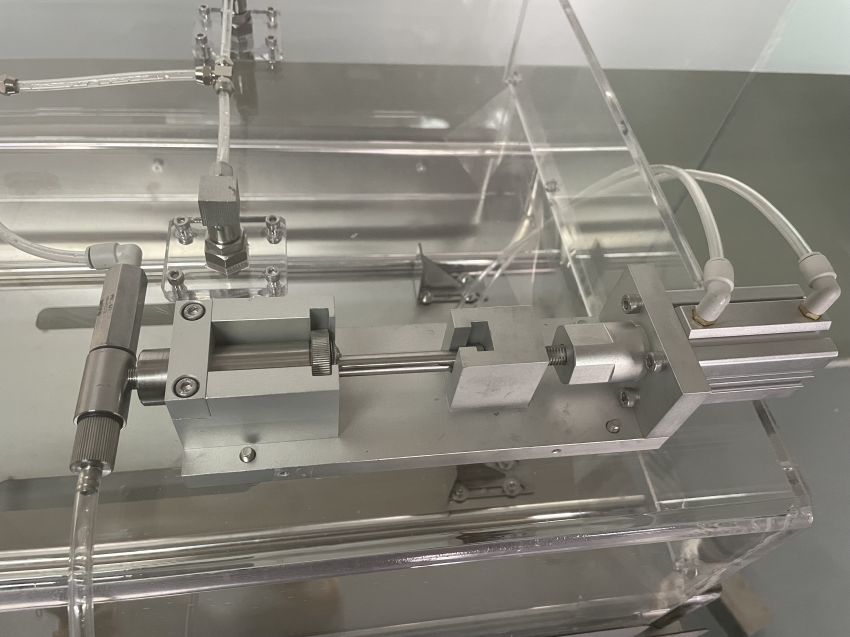

8.Pneumatic piston

The spray pressure comes from a piston working by a air cylinder. This piston is installed in the stainless steel needle cylinder. If everything works normally, there is no need to open this part of the machine. If you want to change the spray dosage, you can open the cap on the piston structure. Do not put your finger between the back of the piston and the spray volume adjusting screw.

The spray dosage will increase when rotating in the arrow direction, and will decrease in the opposite direction.

9.Standard procedures

If all parts of the machine are ready, you can work according to standard procedures. If they are not ready, please read the relevant installation chapters in the manual.

Make sure all connecting tubes are connected properly and the nozzle is installed properly. If necessary, adjust the amount of spray as described previously. Fill the vaccine barrel with vaccine solution and connect the air compressor.

Place an empty chicken box on the machine and spray it for several times to fill the piston cylinder with vaccine. Place the chicken box on the guide rod and gently push it towards the back of the machine. The piston will start spray. After the spray, you can remove the chicken box and replace it with a new one.

If you need to add vaccine to the vaccine barrel, it is recommended that you add it before the vaccine is used up. This can prevent air from entering the piston cylinder. Please make sure to stop vaccination when adding vaccine.

After finishing all spray vaccination, you can add several hundred milliliters of water to the barrel and spray (using an empty chicken box) to clean the connecting tube and nozzle.

10.Maintenance

Often

Please place Regal Spray Immunization Machine in a clean and dry place, away from dust and direct sunlight. Do not expose the spray box to the sun or heat it, otherwise the internal and external structures will be damaged.

After use, spray some clean water to clean the piston, connecting tube and nozzle. Wipe all surfaces with a wet towel. You can dip some industrial alcohol or methanol for cleaning. Do not use any disinfectant on the surface that may come into contact with the vaccine.

Remove the connecting tube on the top of the vaccine barrel, wash it with clean water to dry. Clean the filter head at the suction end of the vaccine. If you want to clean the barrel in the pressure cooker, unscrew the connecting tube and metal connector.

Regular

Clean and disinfect the vaccine tube;

Clean the piston barrel and the inside of the piston (lubrication), and replace the piston sealing ring after every 10000 movements;

If the piston cannot enter the bottom of the barrel or it is difficult to touch the bottom, the piston length needs to be adjusted;

Clean the suction head at the top of the syringe;

Replace springs, pads and vacuum system balls (every 10000 chicken boxes or according to the vaccine you use for spray);

Confirm whether the air filter head is clean, and clean or replace it if necessary;

Adjust the air pressure: pick up the knob, turn it and push it back;

Screw the plastic cover for easy cleaning;

30 micron air filter head

5 micron air filter head

Check the spray status of the nozzle and whether it needs to be cleaned or replaced;

Check the coverage of spray (chicken box with chicken);

Check the air quality in the compressor (clean weekly).

12. Troubleshooting

|

Problem |

Checking |

Solution |

| Poor air connection | Connector | Replace connector |

| No air arrival | Compressor Intake tube |

Turn on the compressor Ensure air inflow |

| No air in machine | On/Off button Pressure regulator |

Put in the correct position Open to let air in |

| Pressure monitor shows 0 | Tube connection Pressure monitor |

Connect the tube Replace the pressure monitor |

| Pressure monitor does not return to 0 | On/Off button Pressure monitor On/Off button |

Put in the correct position If it is locked, it needs to be replaced If it is broken, it needs to be replaced |

| No spray | Check pressure Connection of tube and piston Spray control lever Spray control lever in the regulator box |

Minimum 0.4Mpa Connect the tube correctly Replace the spray control lever |

| Start spray when the chicken box moves | Connection of tube and piston | Exchange the location of the tube |

| Slow or no resetting of piston rod | Air regulator on tube and piston Metal ball and spring at the entrance |

Left rotation Clean or replace |

| Air bubbles enter the piston barrel | Vacuum system Intake tube Vaccine level |

Fix all parts Connect or replace Add vaccine if necessary |

| Vacuum in piston | Filter head for entering vaccine Suction head Filling speed |

Clean the filter head Slow down(Right rotation) |

| Unable to push the piston | Pressure Spray control lever Spray control lever in the regulator box |

0.4Mpa minimum Connected/adjusted Connect or replace |

| Push the piston slowly | Pressure Suction head Nozzle tube Nozzle |

Minimum 0.4Mpa Clean Clean Clean |

| The amount of spray is less than the set amount | Suction head Loose piston |

Clean Adjust the front or adjust the dosage nut |

| Piston collides with barrel | Piston fixation | Adjust |

| Vaccine leakage in piston barrel | Pads | Replace and lubricate it |

| The nozzle can't spray vaccine | Vaccine tube and nozzle | Clean or replace |

| The state of spray is not fixed | Nozzle | Clean or replace |

| Vaccine leakage | Tube and its fixation | Connect or replace |

DETAILED PHOTOS

|

|

|

|

|

|

|

|

Online Message

Online Message